Eton shirts have long been sought after by those in the know. But a recent North American push, accompanied by the opening of flagship stores in Santa Monica and NYC, has brought the brand a much greater degree of attention of late.

Born from humble beginnings, but since transformed into an internationally recognized design house with a sizable fanbase, today the Eton brand displays a certain swagger. Creative director Sebastian Dollinger insists that the company’s products are second to none within the ready-to-wear sector.

But do Eton’s shirts genuinely deliver on quality, fit, and style, or is it all just marketing hype? In this product review, i’ll briefly cover some history of the brand and then share my own experience with the fit and overall quality of these shirts.

Overview

Founded in the small Swedish town of Gånghester back in the 1920s, Eton has been making shirts for approaching one hundred years now. However, like many “heritage” brands, the full story is a little less romantic: the once family-owned company having been sold to a private equity firm in 2012, and then flipped to another investment group just four years later.

Unlike many such buyouts though, Eton’s new owners were not foreign investors, but fellow Swedes. What’s more, the founders’ grandson remains onboard as CEO. Dollinger, too, has history in the business, having practically grown up in it alongside his father, in whose footsteps he now follows as creative director. Although the brand’s products have been popular in Europe for several decades – particularly in the UK, where they were Harrods’ best selling shirts during the ‘90s – it’s only since the more recent change in ownership, and Dollinger’s arrival as creative director, that things have truly taken off on a global scale.

Dollinger’s primary contribution has been realizing that if Eton were to remain competitive, it would need to double down on its bread-and-butter office wear designs, while also rejuvenating itself by offering some quirkier twists on the classics in a more contemporary fit. Envisioning Eton as a fine shirtmaker for the masses, under Dollinger’s helm the company has tried to appeal to as broad a customer base as possible, yet without compromising on quality and style.

Rather than watering down the label’s core products to meet mass market expectations, Dollinger instead achieved this by expanding the brand’s product range. Now there is something for everyone: from the man in finance who never deviates from blue and white, to the Pitti peacock in all his flamboyance. And so today you’ll find plenty of eccentric prints – such as flying bananas or tropical fish – alongside more corporate-approved classics.

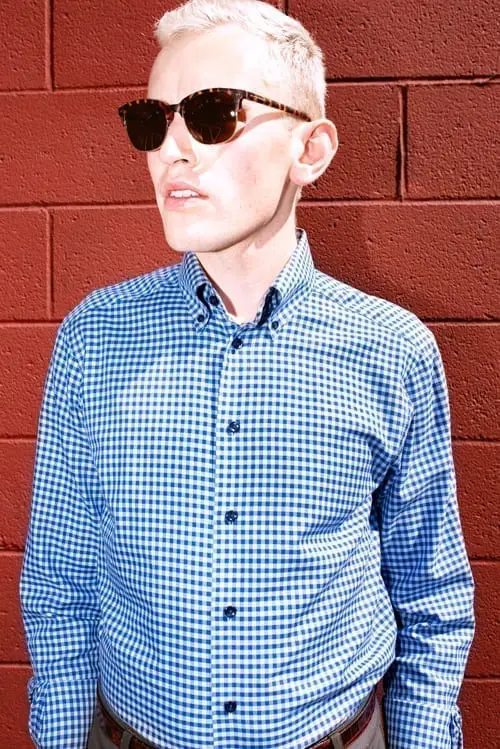

Cut and Fit

Reflecting the brand’s quality-shirts-for-all ethos, Eton offers four different fits. These range from the Classic’s loose ’80s-style silhouette, through to the Contemporary, the Slim, and the rakish Super Slim at the far end of the spectrum.

You’ll have to experiment to discover your own correct fit. My first Eton shirt – a regular fit 15 1/2 – fit well at the neck. However, a good deal of extra fabric had to be trimmed from the sides of the shirt though in order to make it fit my undernourished trunk. There’s nothing inherently wrong with the shirt’s design, but the standard slim fit is definitely better in my case.

A good inch and a half of fabric also had to be removed from the sleeves in order to make them fit properly – and this despite my notably simian limbs. From speaking to others, though, it’s evident that Eton’s generous sleeve length is a common issue. The brand even offers a model with an extra-long sleeve design (perhaps something to consider before shopping online for secondhand Eton shirts).

Fabric

For most people, the truly stand-out feature of an Eton shirt is simply the quality of its cloth. Eton is well known for having invented non-iron fabric in the early ‘90s, and their shirts travel very well; remaining unruffled even after a long flight. Invariably it’s also a real pleasure to have their shirt fabric next to your skin all day long.

From experience though, I’ve learned that ultra-softness of this kind is often less due to the type of cotton used than it is down to the type of “finish” applied to the fabric after milling. Finishing is a somewhat vague term that encompasses a whole range of mysterious processes, from heat treatments and combing techniques through to the application of chemical coatings.

With the latter, there’s a risk that the initial smoothness wears off after wearing the shirt a few times, presumably as the chemical finish is removed by washing. Indeed, even some quite costly shirt brands can shed their initial sheen over a surprisingly short period of time. And on the flipside, if instead the chemicals remain, you have to wonder what these compounds might be doing to your body as they are absorbed by your skin over the course of the day.

Thankfully though, all of Eton’s fabric finishers have achieved Oeko-Tex’s Standard 100 and STeP accreditation. While my understanding is that these environmental standards don’t entirely rule out the use of chemical finishes, they do guarantee that any chemicals used are not harmful to either humans or the environment (for example, some other brands’ finishing processes apparently involve the use of formaldehyde!).

As it is though, Eton’s wrinkle-free effect is reportedly not achieved by means of a chemical coating at all, but instead down to a mechanical treatment that alters the fibers of the cloth itself. Although we can’t confirm the veracity of this claim, chemically-treated non-iron shirts can often be unpleasant to wear, and that’s definitely not the case here. What’s more, after a good few wears and washes, my Eton shirt still seems like new.

Style

The design of a dress shirt is a collective effort that has been perfected over centuries. And with its impressive history, Eton has had plenty of time to get things just right in this department. Dollinger is frank in saying that the products he designs are never dictated by a desire for self expression, but that instead it all comes down to what is right for the shirt itself, and for the brand more generally.

But it’s easy to imagine that a designer might want to have a little more fun in their job than merely updating collar sizes every few years in order to keep abreast of fluctuating suit lapel dimensions. And as shirts tend not to vary massively in design, it also must be extremely challenging for a dedicated shirt brand such as Eton to set itself apart from the hordes of competitors all peddling what are essentially near-identical products.

Presumably this is why Eton is now in the business of “reinventing the classics,” as Dollinger puts it; so as to offer something new to a market that is already fully saturated with satisfactory business basics.

But it can be dangerous to mess with the classics. And no matter how well-intentioned a designer may be, the more s/he tries to add something new to the tried and tested shirt formula, the more it just risks detracting from the final product. Bad design is frequently the result of trying too hard; whereas good design can sometimes just mean knowing when to stop.

Thankfully Eton’s crimes in this department are relatively minor; mostly restricted to misdemeanors such as contrasting floral fabric inside collars. A detail that admittedly may appeal to some customers and is in any case not visible when the shirt is worn.

Occasionally, though, Dollinger’s desire to innovate can manifest itself in more evident ways, such as a mix of brightly colored buttons running down the front placket, piped buttonholes, or contrast-color cuffs. At times these flourishes work; at others the result is more like something you would expect to find under the category “fashion shirt” on Alibaba.

Details and Construction

While Eton still operates from its original factory premises in the south of Sweden, most of their shirts are now made abroad in Estonia, Lithuania, Macedonia, and Romania. With only the pricier (and superior quality) DnA line currently produced in-house. Overall though, the quality of manufacturing is perfectly durable and even shirts from the main line are likely to last a good many years before they’ll need replacing.

Eton’s shirts attract a lot of fanboy nerdery, with aficionados frequently obsessing over minute changes to the design that would escape the notice of most other wearers. But while Dollinger understands that the reputation of his brand rests on maintaining the high standards of construction and fit that have made Eton so popular over the years, he has surprisingly little time for sartorial orthodoxies.

The buttons on main line Eton shirts are not pure mother of pearl, but instead a mixture of MOP dust and plastic. While this may sound like a cost-cutting measure, I’ve previously encountered Italian bespoke shirtmakers who also prefer such buttons, as they are apparently much less prone to snapping than real mother of pearl can be. Similarly, a quick inspection of an Eton shirt reveals that their sleeve seams line up with those of the body. This is a sign that the body and sleeves were assembled simultaneously: a technique that is usually considered inferior to first putting together the body and then adding the sleeves, as you would with a jacket. To be sure, it’s a trait more commonly found on bespoke shirts, but even some high-end RTW products within this price bracket come with offset seams.

Meanwhile, for many style-geeks a split yoke might be considered the holy grail of shirtmaking. Yet Dollinger dismisses this method not only as unnecessarily fussy, but also as structurally weaker than a single yoke design.

Despite possessing numerous tailor-made shirts, I confess to not owning even a single shirt with a split yoke. While this likely tells you something about my bank balance, it perhaps says even more about the real-world merits of the split yoke technique.

To be sure, a split yoke certainly has it’s legitimate uses, but they are primarily to be found in two very specific scenarios:

- When the fabric is striped and the designer wishes to create an attractive chevron effect where the two halves meet by cutting the fabric at an angle.

- When a shirt is being made bespoke, and the client has shoulders that slope at different angles (as indeed most people’s shoulders do). Here an asymmetrical split yoke will provide a better fit for the wearer.

Clearly though there’s no structural advantage to using a split yoke when the shirt is mass-produced, as the slope of the wearer’s shoulders cannot possibly be known in advance. In any case, it seems debatable just how much of an advantage is really offered here: cotton is a forgiving fabric, and will likely adjust to the body of the wearer enough to hide all but the most acutely asymmetrical of shoulders.

Dollinger also frowns upon gusset tabs – the little pieces of fabric that sometimes cover the bottom of side seams where they meet the hem. While often pitched as a decorative and structural improvement, Dollinger argues that in reality gussets are just a method of hiding poor workmanship in what is apparently quite a tricky part of the garment to sew neatly.

It’s entirely possible that Dollinger’s objection to these details comes down to a Scandinavian preference for simplicity. And while the design of seams, yoke etc. might appear important in theory, all that actually matters is how the shirt looks and performs when worn.

Or he might just be trying to spin cost-cutting measures in a more positive light.

Yet a quick scan of my closet reveals that, of over half a dozen favorite shirts, only one has off-set sleeve seams, most have gussets, and none have a split yoke. From this I can only conclude that fabric, color, and overall proportions are in practice far more important factors in determining the desirability of a shirt than any showy sartorial techniques.

However, the one Eton design detail that remains universally unpopular – even among otherwise enthusiastic customers – is the fact that their collar stays cannot be removed. After repeated ironing, sewn-in collar stays will eventually become visible under the collar fabric, making them something of a liability. This is a design decision that undoubtedly diminishes the functional life of a shirt, and is thus not in keeping with Eton’s stated commitment to producing long-lasting, sustainable products.

Indeed, while the merits (or otherwise) of the other construction methods we discuss above are likely open to a degree of debate, switching to a removable collar stay design would be the single most convincing move that Eton could make right now.

The Bottom Line

Although Eton’s creative director perhaps overstates things slightly when he claims to make the world’s best ready-to-wear shirt, the brand undoubtedly produces some of the better dress shirts available within this category.

While it’s true that Eton shirts can be quite costly if paying full retail, they are well worth the investment when purchased on sale. Meanwhile, lightly used Eton shirts can often be picked up for very reasonable prices and are undoubtedly one of menswear’s better kept secrets.

Thanks for reading – check out more of my product reviews here and be sure to browse the store at Menswear Market for regular arrivals of pre-owned, gently used Eton shirts.

Disclaimer: all items are pre-owned. Menswear Market has no relationship with the brands described and/or pictured on this website. Trademarks are owned by their respective brand owners